A Response to Gingerhousing Crisis: overly engineered gingerbread house

December 17th, 2022 | by Saren Tasciyan | posted in 3D Design, 3D Printing

It is Christmas time! Declining temperatures and snow is around the corner. Ginger people need a roof over their head! It is time to give them that before they mysteriously disappear again. But unlike last year, this year we aim for precision and engineering, only to be improved next year. We will use 3D design, modeling and printing. We will cast ginger bread walls and bake to be assembled at the construction site. And then we said “Let there be light!”, so I soldered LEDs and powered them with a 5V power supply lying around. And of course with lot’s of “snow” and glitter.

Before everything, this gingerbread house was not meant to be eaten! Including 3D printed parts in your kitchen/cooking processes may introduce serious health hazards into your food! Please do your own research! I highly advice against it unless you really know what you are doing and it is easy to miss important details!!! That being said…

Here is how we did it…

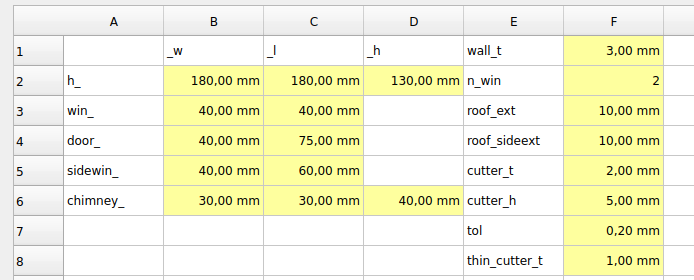

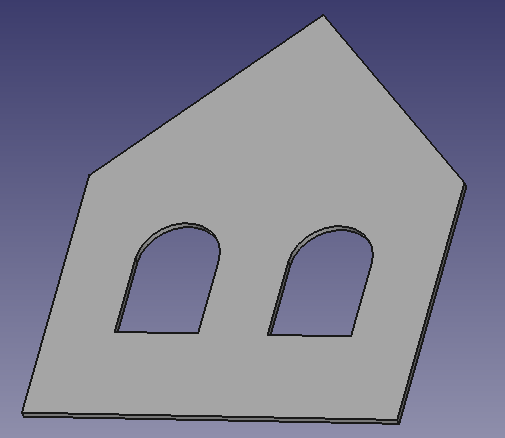

First, we drew the outlines and sketched on a paper. Then I made the models in FreeCAD. Of course when we model something, we model parametric(ally)!

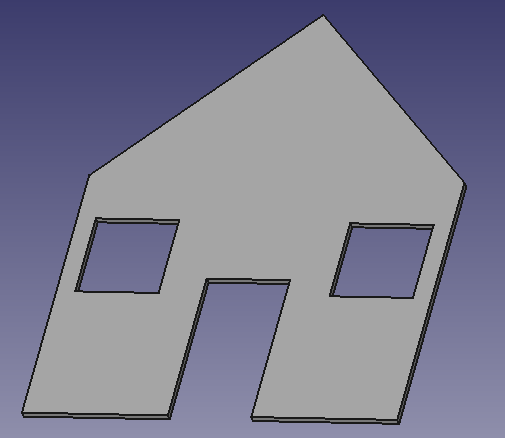

Then we make the pieces as if they are parts of the house…

Then from these models we assemble an house to see how it looks…

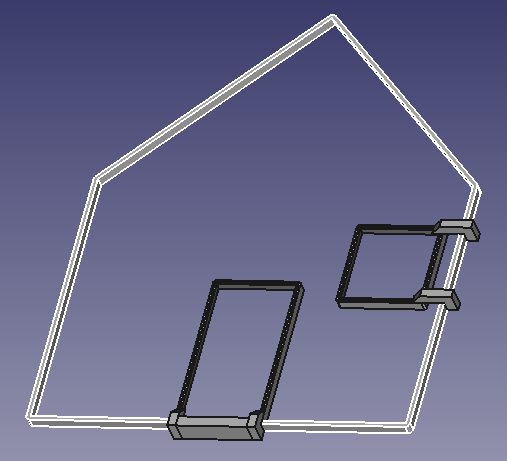

Everything was fine, so we moved to make the cutters…

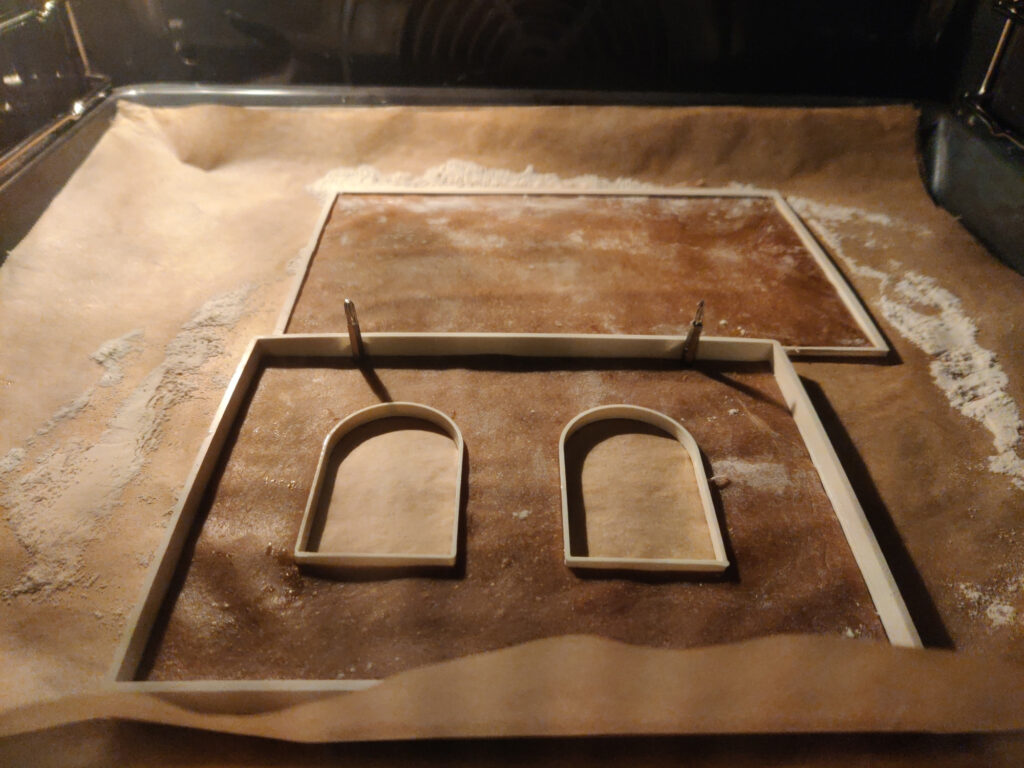

So we baked some expired ginger bread dough (bought ready made) with buttered 3D printed cutters…

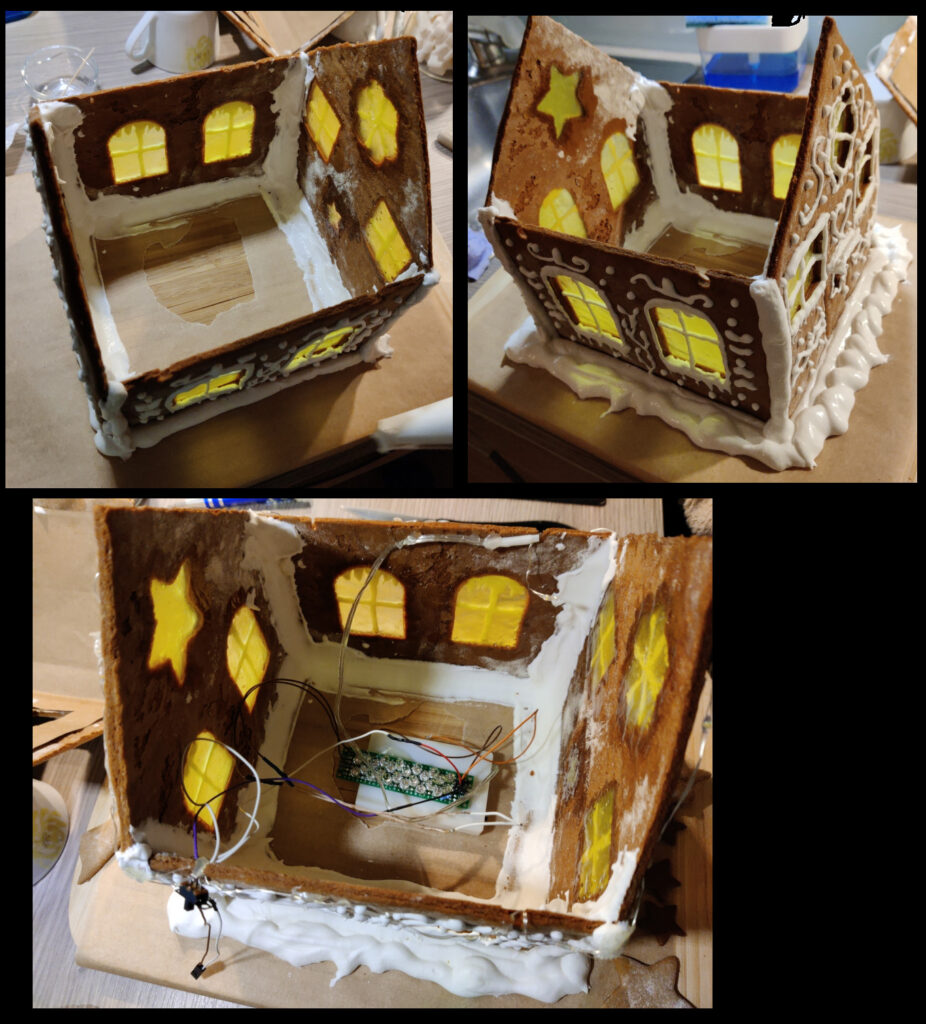

Every house needs “glass” windows. These windows are quite sweet and lemony.

Roof requires some paper support with the snow/cement/glue material (edible).

Then the walls came together with decoration and electrification.

Some cabling work

Roof, chimney and snow

Ginger person seems to be happy…